A little help and guidance help avoid errors. It is well known that human error is a leading cause of many workplace incidents that result in injury, downtime and financial loss. Helping workers avoid this is possible with this amazing technology called Augmented Reality or AR as it is commonly referred to.

Ask any industry expert and they would confirm that drawings, procedures and documents are really essential to do their work and there’s no running away from it. AR technology has superb solutions to help employees be successful in their roles. There would not be a need to carry clunky manuals, long checklists, big drawings to do their tasks and work can be simple, efficient and fun!

Industry 4.0 refers to the Fourth Industrial Revolution, which is actually happening, right now!. It is a bunch of technologies that bring about rapid changes in manufacturing with greater digitalization, automation and enhanced connectivity. AR technology has been around for some time and is being adopted quite rapidly by the manufacturing industry.

It is well known to many experts that one of the key technologies is Augmented Reality in Industry 4.0. Another technology that is closely associated with AR is Virtual Reality (VR). It’s important to know that industrial AR VR applications are being deployed in many areas such as design, construction, operations, maintenance, safety and reliability.

Benefits of AR in Manufacturing Processes

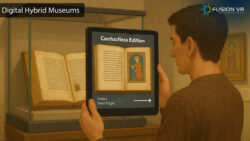

AR is easily implemented with a simple smartphone, tablet and wearables. It really doesn’t cost much to adopt AR solutions in a factory or plant. AR understands the surrounding physical environment and overlays information on the chosen device. The AR experience delivers on improved productivity, safety, reliability, cost savings and increased efficiency of manufacturing processes.

AR is capable of making a unit a smart factory and employees even smarter. Using a wearable such as AR goggles, an assembly line worker can receive instructions on the exact sequence and manner in which tasks and checks need to be done. A flawless assembly not only makes it meet quality standards but is also safer. Error-free operations lead to lesser downtime and improved productivity. If the problem requires some expert assistance, it can be readily provided remotely. Here the expert sees the issue directly through the device or wearable and communicates the necessary instructions in real-time.

Drawings that are necessary to understand the internal arrangement of complex machinery may not be needed. AR technology brings 3D models of the equipment to your handheld and gives you specific information related to the part or section that you are interested in. It saves time and enables the worker to be more efficient and productive.

AR is used to make design processes collaborative by engaging and involving experts from any part of the globe. The connectivity is so advanced that we can work simultaneously and dramatically shorten the development cycle. AR training has modules and learning objectives that are gamified for the workers of the digital generation. Learning is more fun and the retention and confidence gained are manyfold with time and cost saved.

To help you in adopting AR, you need a friend who is an expert in digitalization and Industry 4.0 technologies. Reach out to Fusion VR and we’ll be your best partner for growth and success in the 21st century.