Have you ever wondered about the term that is used to indicate Augmented Reality, Virtual Reality and Mixed Reality collectively? It is all classified under an umbrella term called Extended Reality (XR). The emergence of Extended Reality technology (XR) has promised to revolutionise the manufacturing industry, with the potential to improve efficiency, and productivity, reduce costs and enable greater collaboration.

XR technology creates a digitally enhanced version of the physical world. This technology is rapidly being adopted in manufacturing, allowing engineers and technicians to visualise processes, interact with part designs, and collaborate with remote teams more effectively.

Extended Reality Companies are leading the way in revolutionising the manufacturing sector by utilising augmented and virtual reality technologies to reduce costs and improve efficiency. One of the significant applications of XR in manufacturing is in the design and engineering process. Using XR, engineers and designers can create 3D models and simulations of their products, allowing them to visualise and interact with the product more realistically. This can improve the accuracy of designs and enable engineers to identify potential problems or design flaws even before the product is manufactured.

Extended Reality (XR) is quickly becoming an essential tool in the manufacturing industry. XR combines virtual reality (VR), augmented reality (AR), and mixed reality (MR) to create a more immersive and interactive environment. It can be used to visualise and interact with data, allowing manufacturers to make more informed decisions faster.

XR can improve the efficiency of the manufacturing process. By providing an interactive 3D view of the manufacturing environment, XR can help workers visualise and learn the entire process but also identify potential bottlenecks or inefficiencies. This can be used to optimise the production line and improve the overall speed and efficiency of the manufacturing process. XR also enhances collaboration between teams.

Enhancing Customer Interaction with XR in Manufacturing

XR technologies enable manufacturers to create more efficient processes, optimise worker performance, and provide better customer service. By utilising XR, manufacturers can provide technicians with real-time remote assistance and give the workers more comprehensive training. Additionally, XR can reduce manufacturing costs by providing an interactive 3D view of parts and components that can be manipulated and annotated before they are produced.

For example, XR can guide workers through the assembly process or help them identify potential problems with a product before it is fully assembled. XR can also optimise the maintenance process by providing a virtual representation of components of the product and allowing workers to identify potential problems and resolve them quickly.

Extended Reality in manufacturing can be used to simulate the production process and production line. This allows manufacturers to identify potential problems before they occur and plan for contingencies. XR will also enable manufacturers to create and test configurations, such as various machine setups or assembly line routes, without building them.

Extended Reality in manufacturing industry also offers a way to train employees on the job. Using XR simulations, employees can learn the production process without physically being in a factory. This can be especially helpful for large-scale or hazardous operations where employees may be unable to move around or safely access. .

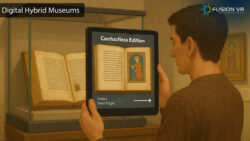

Finally, XR can be used to create better customer interaction. For example, manufacturers can use XR to give customers a 3D view of their products, allowing them to explore them in detail before they make a purchase. XR is also used to enhance customer service by providing customers with an immersive experience when interacting with the product. For example, a customer could view a product in a virtual environment and be able to interact with it and explore it.

The manufacturing industry has seen a massive shift in recent years due to the introduction of extended reality (XR) technologies. XR is revolutionising the way products are made and maintained.

In conclusion, extended reality in manufacturing promises to revolutionising the industry, allowing for more efficient and cost-effective production. This technology has the potential to streamline processes and create new opportunities for manufacturers to explore, such as virtual prototyping, improved training and education, and enhanced customer experiences. With the proper implementation strategy and the right technology, extended reality can help manufacturers to become more agile and competitive while providing them with the tools to create more effective end products.