Hyperconnected Metaverse is no more a science fiction. Our physical and virtual worlds have started converging in a fast-phase. This disruption is creating heaps of opportunities in the industrial landscape which we wouldn’t have thought of possible in the past. In this article, let’s explore the strong biological facts behind the success of these immersive technologies and why are they so crucial in training industrial workforces.

Unrealized Facts

The ultimate objective of any industry which is currently into digital-transformation is to create new business models which can Increase their productivity, safety & profitability. While most enterprises having a keen focus on ‘How to make their machines & processes smarter’ overlook the very serious fact that “only 20% of employees have the Skills needed for both their current roles and future career, according to Gartner, 2018”. In order to remain/improve the competitive edge, Training departments of factories has to adopt alternate training methodologies which can truly track the efficiency of the training with accurate.

The Statistics Vs Strategic Challenges

Statistics and case studies proves that most workers are practical learners, acquiring 70 percent of their skills and knowledge from experiential learning. But, in reality, learning every production processes and emergency scenarios of a factory only by experience will be a very long learning curve. To get the efficiency of a 20 years experienced operator, we need to wait for 20 years. So, the real challenge lies in effective reduction of the time to operator proficiency.

This is where organizations have to make strategic decisions on non-conventional training models and corresponding investments. Part of their digital transformation roadmap, it’s vital to consider investing on intangible assets creation such as digital assets, 3D Mesh-Models & IPs. These are equally important as tangible investments such as upgrading the machineries. These are the building blocks for most Industry 4.0 solutions including Virtual & Augmented Reality training modules and Immersive digital twin simulations.

Apart from fear of disruption, decision making is being impeded by usual blockades such as lack of technical knowledge, confusions on defining use cases, uncertainty on ROI and cultural factors. Conventional thinking on employee training such as class-room trainings, refresher courses, group discussions and mockups alone is never going to sustain businesses in the future. Before it is too late, enterprises need to consider adopting the much robust & smarter training methods using the immersive VR/AR technologies.

The Power of Biology in the Success of VR-training

We see our physical world in 360 degree with our binocular stereovision. Visual cues play a major role in our understanding of the environment. Non-visual cues such as sense of movement through neurons from limbs & muscles (Kinesthetics), orientation & balancing sensors which also helps eyes to stabilize while head is on motion (Vestibular) and Proprioception, a subconscious mind which gives the sense of position in space along with auditory, haptics, smell, etc, also contributes to our physical experiences.

With the current immersive technologies a digital replica of the physical counterpart can be created where all the above senses of the users can be simulated and make the brain to believe it’s real. However, one needs to be cautious that unless the experiences are created keeping the above biological factors in mind, the experience will become a nightmare. The brain will go crazy with conflicting sensory inputs.

Once the user got tele-ported to the virtual shop floor, he can interact with / operate machineries and learn things exactly the same way he could learn during on-the-job training/ learn by practice. Experiential learning is the secret recipe behind the tremendous effectiveness of Virtual-Reality (VR) & Augmented-Reality training modules.

In a study published in the journal, Nature Communications, University of California, it’s been found that “as memories are recalled, especially in the hippocampus (small structure in the centre of the brain) different regions of the hippocampus were activated for different kinds of information.

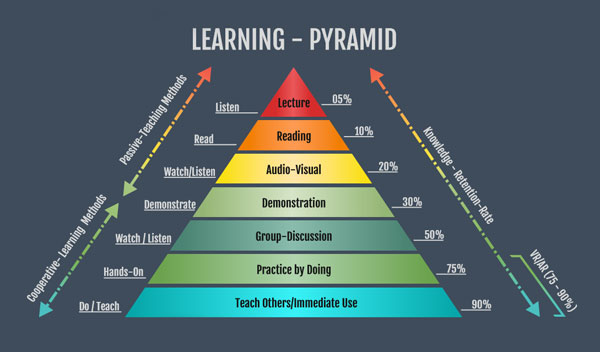

During VR experiences, hippocampus was involved in episodic memories linking both time and space”. This study supports the fact that brain believes the VR-experiences as closer to real experience. Based on the above findings and referring to the “learning pyramid”, the VR-Training model has the potential knowledge retention rate of 75-90%.

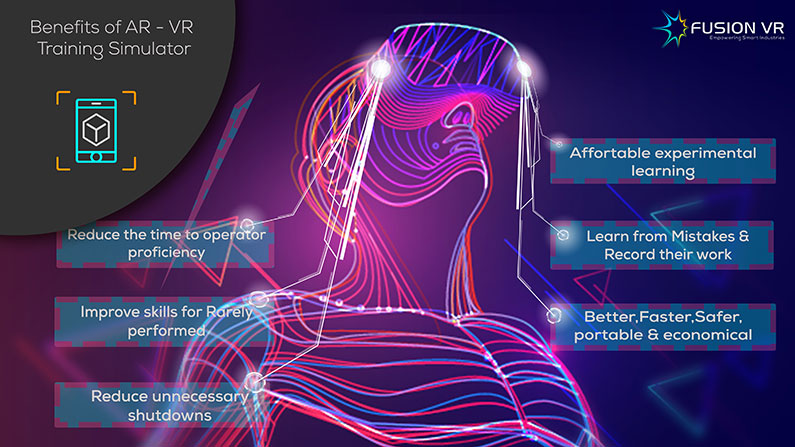

AR-VR Training Simulators Benefits

- VR/AR training is the more affordable experiential learning

- Scenario-based AR/VR simulations allow learners to test their skills, learn from their mistakes, and record their work – all within a no-consequence environment

- Better, faster, safer, interactive, trackable, enjoyable, portable & economical training in a controlled multi-player environment

- Optimize training throughout the plant / shop floor

- Reduce the time to operator proficiency

- Improve operator’s ability to respond in time and act appropriately to emergency scenarios

- Improve skills for rarely performed but safety critical tasks

- Maximize team training, coordination and communications skills between groups

- Reduce unnecessary shutdowns and reduced plant performance due to operator errors

- Capture operator knowledge and best practice multi-functional scalable technology

Conclusion

The success of VR/AR implementation is not just achieved through latest gadgets and technology alone, but needs expertise to choose the correct use cases and lot of imagination to design the experience. Hence, choosing your VR partner also plays a crucial role. To make life easier:

- Look for a VR-service provider with engineering & manufacturing background

- Discuss your pain points & training requirements with them

- Select a simple use-case where the benefits of the VR training results can be physically tracked in the future

- Implement your first Proof-of-Concept (POC) and quantify the benefits

- Justify the ROI and go big to taste the advantage of the early adopters

Read From Source: Economic Times